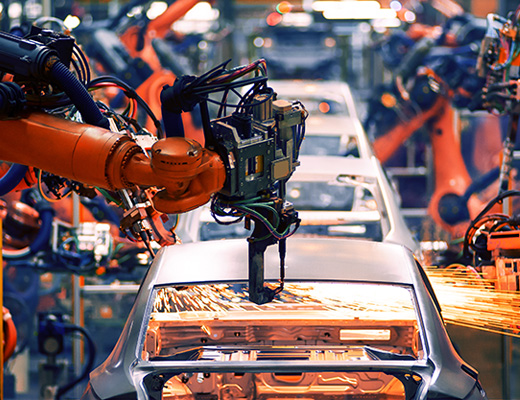

Automobile Industry

The automobile business depends on numerous factors like availableness of good labour at low value, sturdy R&D centres, and cheap production. The business conjointly provides nice opportunities for investment and direct and indirect employment to good and unskilled labour.

Indian automotive business (including element manufacturing) is anticipated to succeed in Rs. 16.16-18.18 trillion (US$ 251.4-282.8 billion) by 2026.

The Indian automotive vehicle business is anticipated to record robust growth in 2022-23, post ill from effects of COVID-19 pandemic. electrical vehicles, particularly two-wheelers, ar doubtless to witness positive sales in 2022-23.

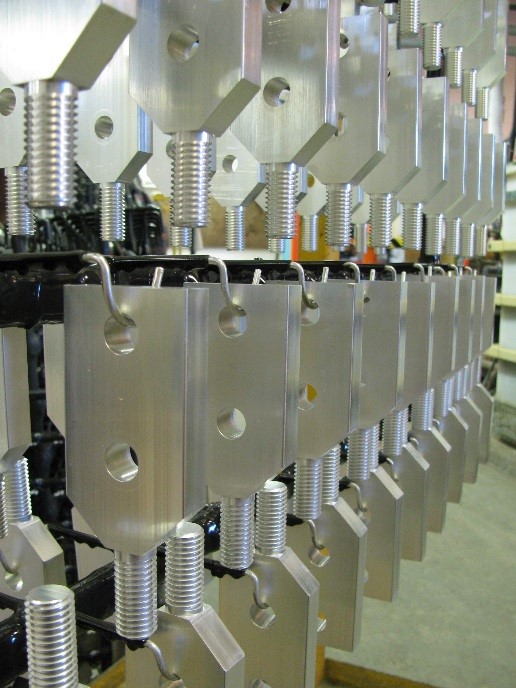

Nickel and Chrome Plating Line

Chrome and electroless nickel plating both work well for various substrate materials. Because the coating deposits onto all surfaces of the component uniformly in the plating vat, you can use both metals for irregularly shaped objects, including those with holes and recesses.

Hard Chrome Plating Line

Hard chrome plating is an electroplating process in which chromium is deposited from a chromic acid solution. Thickness of hard chrome plating ranges from 2 to 250µm. Various types of hard chrome include micro-cracked chromium, micro-porous chromium, porous chromium and crack free chromium. The coating has low coefficient of friction and excellent wear properties.

Plating on Plastic(POP Line)

Rising applications in automotive and electronics industry has been a major factor driving the Plating on Plastic (PO) market growth.Plastic plating is commonly used in many industries for purposes such as corrosion and wear protection, increasing surface hardness, promoting electrical conductivity, or for improving the appearance of a part or component.

Acid, Alkaline Zinc Plating Lines

Alkaline Zine plating is completely automatic with auto dosing, automatic water addition, rectifier in constant current mode and quality management system.Alkaline zinc plating, equally called cold galvanizing, electrolytic zinc coating, or electrogalvanization, uses electrolysis to deposit a layer of zinc on a steel base material in an alkaline medium, i.e., a basic (alkaline) pH aqueous solution.

Copper/Silver Plating Lines

The silver plating of copper will increase the operating temperature of copper alloy conductors. Silver also provides superior solderability and excellent electrical conductivity. When used for plating a copper conductor, silver will enhance the high-frequency transmission capabilities of the wire.

.jpeg) D Square Electroplating Machines Pvt. Ltd.

D Square Electroplating Machines Pvt. Ltd.